Concrete driveways stand up to a lot of pressure over the years. How much do concrete driveway repairs cost when it's time to give it a little TLC?

Get a concrete answer on the right mix for your next project

The most commonly used type of concrete in the U.S. is all purpose concrete, with a PSI of 3,000.

High-strength concrete is often used in residential settings, especially in areas with extra weight demands like outdoor kitchens, driveways with large vehicles, or commercial buildings.

Reinforced concrete uses steel bar or mesh to provide 40,000 to 60,000 PSI, making it suitable for infrastructure projects.

Pervious concrete allows water to pass through it to the sublease drainage area beneath it, making it well-suited to stormwater management.

Did you know that asphalt is classed as concrete, as is terrazzo? There are a dizzying number of types of concrete, and knowing which one is best for your home improvement project will ensure a safe and successful result. From patios and driveways to foundations, roads, kitchen counters, and sewers, concrete is essential in all our lives. Below, we’ll review the types of concrete and their best uses, pros, and cons.

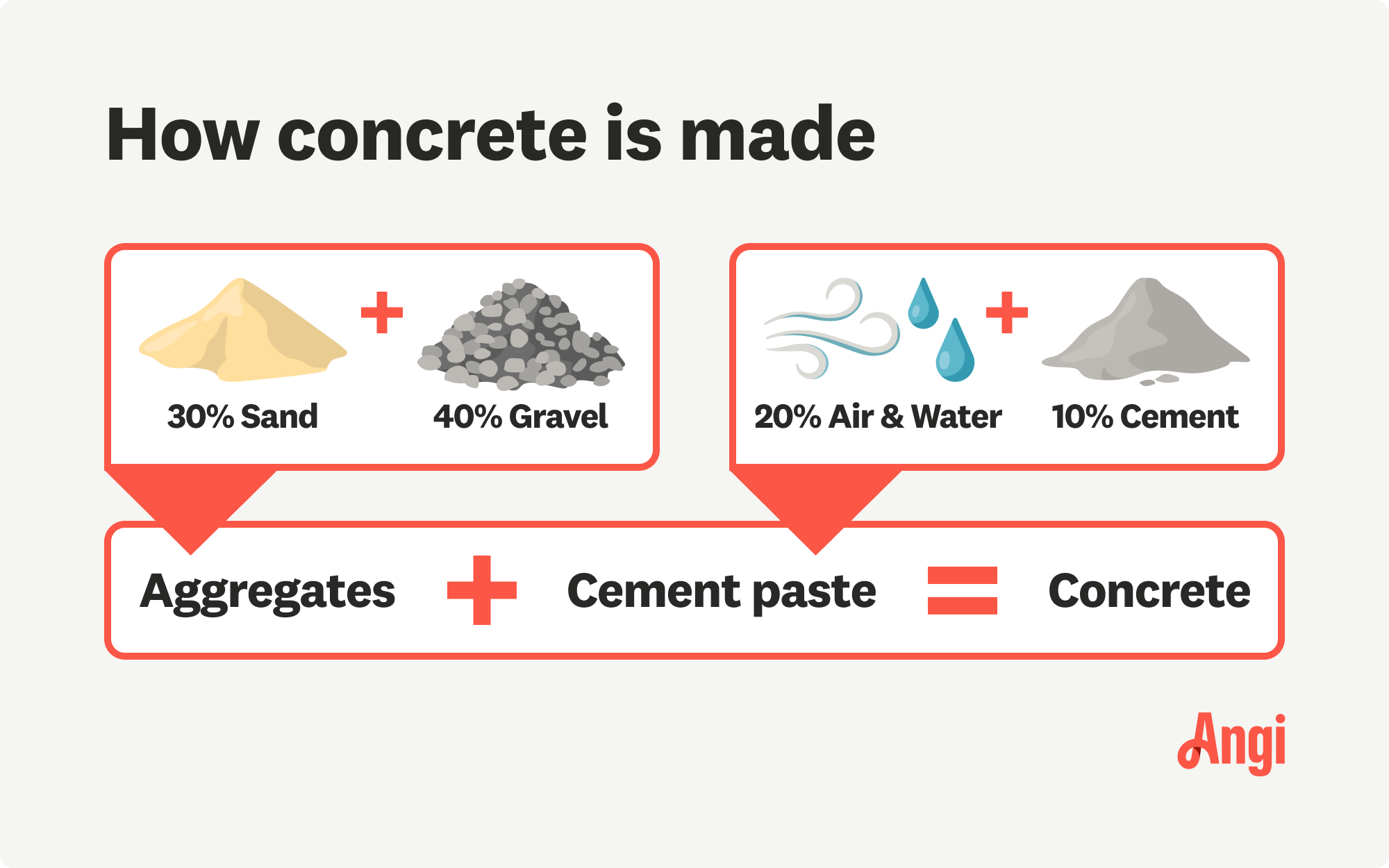

But first, let’s take a look at how concrete is made:

Out of all the types of concrete, all-purpose concrete is the most popular in the U.S. It is made from cement, air, water, sand, and gravel. The ratios are 10% cement, 20% air and water, 30% sand, and 40% gravel. It is mainly used for exterior residential jobs.

The measure of concrete’s strength is its PSI rating. Concrete with a higher PSI rating is stronger, can carry more weight, and is less prone to cracking than concrete with a lower PSI rating. All-purpose is available in 50, 60, or 80-pound bags of dry material. And when you mix concrete with water, it creates concrete with a PSI rating of between 2,500 and 4,000.

A concrete slab costs $5 to $10 per square foot, with most homeowners spending $6 to $8 per square foot or $120 to $170 per cubic yard for materials and installation. If you’re wondering how much concrete costs, the greater the PSI, the greater the cost at $110 to $150 per cubic yard. However, contractors often price according to the size of the job. Contact a local concrete contractor for a customized estimate.

| Pros | Cons |

|---|---|

| Uniformity | Limited PSI strength |

| Time-saving | Slippery when wet |

| Ease of use | Prone to wear and tear |

| Versatile |

Best for: Creating slabs for patios and driveways, building foundation walls, setting posts, and patching older or cracked concrete

High-strength concrete can be mixed and is used similarly to all-purpose concrete. It's often combined with thicker slabs (6 to 8 inches) as extra protection against cracking to withstand heavy items such as machinery (home workshops), hot tubs, outdoor kitchens (patios), and large vehicles (driveways). It is one of the most popular types of concrete for more demanding residential applications.

| Pros | Cons |

|---|---|

| Low permeability | More expensive |

| Withstands high pressure | Special curing requirements |

| Uses less product | Requires skilled labor |

Best for: Thick slabs, floors for home workshops, exterior hardscape with hot tubs and outdoor kitchens

Fast-setting concrete is a pre-mixed variety and hardens in only 20 to 40 minutes (It reaches full mechanical resistance in 28 days.) The process starts in as little as 5 minutes, meaning you should have the base area prepped prior to pouring concrete and work quickly. It bonds well with wood, brick, metal, and plastic. Out of the many different types of concrete on the market, exterior contractors often use this for fence and pergola post settings.

| Pros | Cons |

|---|---|

| Sets quickly | Expensive |

| Easy to use | Prone to cracking |

| Versatility | Durability issues |

Best for: Post setting for fences, landscaping, and mailboxes

Consider crack-resistant concrete mix for sidewalks, patios, floors, steps, or anywhere else where a long-term, crack-free finish is crucial. As the name implies, using crack-resistant concrete reduces the chances of cracking due to ground movement or inadequate reinforcement. The product is simply all-purpose concrete with added fibers that increase its binding properties and give it a strength of around 4,000 PSI.

| Pros | Cons |

|---|---|

| Visually appealing | Expensive |

| Durable | Requires expert application |

| Needs specialty sealants |

Best for: Steps, walkways, driveways, patios, sidewalks

Reinforced concrete combines traditional cement concrete with reinforcements (steel bar or mesh) to provide greater tensile strength than regular concrete. The use and strength of this concrete type depends on the PSI, which varies according to the type and amount of reinforcements used, but it normally ranges from 40,000 to 60,000 PSI.

| Pros | Cons |

|---|---|

| Strength | Heavy |

| Durability | Frequent maintenance |

| Cost-effective | Design limitations |

Best for: Building foundations and commercial and infrastructure uses such as roads, precast structures, floating structures, hydro-power tunnels, irrigation canals, and drains

Unlike conventional concrete that’s poured into forms onsite and left to cure, precast concrete is poured into molds offsite. The molds are removed and can be reused. The precast concrete is left to cure and then transported to the job site.

| Pros | Cons |

|---|---|

| Speed | Difficult to transport |

| Controlled environment | Limited modification |

| Design versatility | Requires expert installation |

Best for: Concrete walls, slabs, columns, beams, stairs

Lightweight concrete is made from lightweight coarse aggregates, such as shale, clay, or slate, and it has a particularly low density—thus the name. Specifically, it has an in-place density of 90 to 115 lb/ft³, whereas the density of regular-weight concrete ranges from 140 to 150 lb/ft³. Lightweight concrete uses more water and more porous aggregates than regular concrete.

| Pros | Cons |

|---|---|

| Low density | Lower strength |

| Improved thermal insulation | Susceptible to extreme weather |

| Easy to use | High cost |

Best for: Partition and panel walls in frame structures and wall insulation

Polymer concrete uses a polymer binder within the aggregate in place of hydrated cement, which gives it good adhesion, making it stronger and less porous than regular concrete.

| Pros | Cons |

|---|---|

| High strength | Higher cost |

| Less corrosion | Poor insulation |

| Durable | Low fire resistance |

Best for: Repairing corroded and damaged regular concrete, industrial construction, marine applications, and prefabricated structural components like manholes and median highway barriers

Prestressed concrete puts compressive stress into the structural member (the metallic component within the concrete like steel) before the concrete is used, thus strengthening the ability of the concrete to span larger distances than conventionally reinforced concrete elements. It is less susceptible to cracking and deflection (the degree to which a component or structure changes shape when a load is applied).

| Pros | Cons |

|---|---|

| High strength | Expensive |

| Lower defection | Complex to manufacture |

| Durability | Increased construction costs |

Best for: Floor beams, piles and railway sleepers, bridges, water tanks, roofs and airport runways

Stamped concrete uses large rubber stamps applied to wet concrete to replicate the texture and look of stone, brick, and even wood. Combined with appropriate coloring, the results can be pretty life-like.

One question on most homeowners’ minds is how much does a stamped patio cost versus paying for cobblestones or pavers. There are considerable savings. Expect to pay $3 to $5 per square foot for stamped concrete over the concrete slab cost, which is $4 to $8 per square foot.

| Pros | Cons |

|---|---|

| Affordable | Slippery when wet |

| Durable | Difficult to repair |

| Easy to maintain |

Best for: Patios, driveways, pathways, outdoor shopping malls, and pool decks

Pervious concrete is comprised of Portland or blended cement, water, and uniformly sized aggregate, with open spaces making up about 15% to 20% of the hardened mass. Noticeably absent is sand. When left untreated, pervious concrete resembles lava rock. It is somewhat clumpy and brittle.

Pervious concrete allows water to pass through it to the sublease drainage area beneath, which is why it’s used in stormwater management systems. It can also be colored and stamped to create a more aesthetically pleasing design.

| Pros | Cons |

|---|---|

| Heat mitigation | Low strength |

| Sustainable | Requires regular maintenance |

| Effective at managing stormwater | Climate sensitive |

Best for: Stormwater management in pavements, driveways, parking lots, greenhouses, and low-traffic roads

You can think of air-entrained concrete as the equivalent of a concrete mousse. It contains billions of microscopic air particles per cubic foot to relieve internal pressure on the concrete, allowing room for water to expand when it freezes, offsetting the risk of freeze-thaw action.

It is produced using air-entraining Portland cement or with air-entraining agents under the guidance of trained specialists as it is mixed on the job site. The air usually comprises 4% to 7% of the overall concrete volume.

| Pros | Cons |

|---|---|

| Freeze-resistant | Lower strength |

| Easy to use | Higher maintenance |

| Durable | Climate sensitive |

Best for: Buildings, bridges, and highways

High-density concrete is about 25% higher in density than regular concrete (It weighs 6000 to 6400 kg/cu.m) and is produced using various heavy-weight aggregates, including barite, ferrophosphorus, limonite, hematite, ilmenite, magnetite, goethite, steel punchings, and steel shots. The mix proportions of high-density concrete are the same as for standard concrete, but mix batch sizes are generally smaller so as not to overload the mixer.

| Pros | Cons |

|---|---|

| Blocks radiation | High cost |

| Can be used as a counterweight | Requires more oversight |

| Highly durable | Difficult to use |

| Limited availability |

Best for: Radiation shielding in nuclear power plants, when X-rays, gamma rays, and neutrons are being used, or for counterweights when high density is required

Commonly referred to as asphalt or blacktop, there is a marked difference between an asphalt and a concrete driveway, where asphalt is most commonly seen, along with roads and parking lots. Asphalt concrete is a black substance comprising mineral aggregate-bound bitumen (a thick, sticky, black, liquid, or semi-solid form of petroleum), compacted and laid in layers.

There are several types of asphalt mixes—hot mix, warm mix, cold mix, cut-back, mastic, and high modulus. Most people are familiar with hot mix asphalt, which is used to coat roads and driveways when steam rises from the surface.

| Pros | Cons |

|---|---|

| Quick to install | Design limitations |

| Pliability | Heat restrictions |

| Load-bearing capabilities | Needs resealing |

Best for: Roads, parking lots, driveways, airports

Shotcrete is more of a process than an actual type of concrete. This concrete-application method propels concrete and mortar at a high velocity on vertical or overhead surfaces for construction. It can be applied in a dry or wet process. The dry process consists of pre-blended or semi-dampened materials fed into a delivery hose. Compressed air forces the material to the nozzle—where water is added—then sprayed, creating the final shotcrete. The wet process entails mixing all ingredients, including water, into the equipment. Then, the material is pumped to the nozzle, and compressed air is introduced.

| Pros | Cons |

|---|---|

| Speed of installation | High amount of waste |

| Accessibility | Requires expertise |

| Cost-effective | Hardens quickly |

Best for: Bridge restoration, dams, sewers, marine structures, mining, tunneling foundations, swimming pools

Glass concrete uses waste glass, ground down to a powder as aggregate (in combination with or in place of sand and gravel) to create colorful terrazzo or granite and marble-like finishes. This process gives the concrete a sparkling iridescence. It is often used as a decorative finish.

| Pros | Cons |

|---|---|

| Naturally cool | Prone to chemical attack |

| Strength | Expensive |

| Sustainable | Brittle |

Best for: Interior flooring, counter-tops, fireplace surrounds, furniture

Self-consolidating concrete (SCC) is a fluid mixture poured into place and flows and consolidates under its own weight. It is self-compacting and can fill spaces without bleeding and segregation.

| Pros | Cons |

|---|---|

| Lower labor cost | Sensitive to environmental conditions |

| Ideal for tight spaces | Higher material cost |

| Smooth, seamless finish | Low elasticity |

Best for: Reinforces steel with space restrictions, floors, and slabs

First class experience dealing with Sheila, she took a personal interest in not only the job, but me as a customer. She kept me updated on the situation and progress. Most importantly, the job was done on time and on budget. Her crew were professional and left the project in excellent...

Mac was very responsive and worked with me. He did an excellent job on sealing my driveway and I would highly recommend Max and his company, Jones Asphalt.

While the materials and communication was good, unfortunately there were some things that left a bad taste and I am not sure I would use them again. While there were some issues that they are addressing quickly, like replacing a part of the door they changed because a piece was smothered...

Five Stars Concrete did a great job on our new driveway! The team was fast, friendly, and the concrete looks perfect. Very happy with their work!

Nick did a complete remodel of my bathroom to include a walk in shower. He was there from start to finish and is extremely detail oriented and ensures complete customer satisfaction. He is very easy to reach with any questions and project was completed on schedule . Nick and his company...

A big thank you to Keith and Mike and their amazing team for a job well done! I needed an extension to my concrete driveway— less than 300 square feet, and they were able to complete the task in about 6 hours, start to finish. The result of all their teamwork and hard labor is everything I...

They did amazing job of pouring a beautiful stamped concrete deck for my gazebo.

Gave a couple different options for the repair of existing driveway. Very professional with fast turnaround and quality work. Completed repairs of 3000 foot driveway in a day.

All the 5 star ratings are deserved. Great company, great experience. Ben was very responsive to all my questions, and very timely on information/quotes. You name it. Cannot say enough - hire them.

Wasn't a complicated job, had to re-hang a few layers of siding that blew off in a storm. They responded quickly and showed up the same day I called. Fixed the following day. Price was reasonable. Very professional and just a great all around experience. I do recommend for anyone in...

From average costs to expert advice, get all the answers you need to get your job done.

Concrete driveways stand up to a lot of pressure over the years. How much do concrete driveway repairs cost when it's time to give it a little TLC?

Whether you’re planning on putting in a concrete driveway, patio, or staircase, use this concrete delivery cost guide to get an accurate estimate.

Need to breathe new life into your exterior stoop? Use this guide on concrete step repair cost to see the price of a professional repair.

Resurfacing a concrete driveway can transform it into a beautiful accessory for your home. Keep reading to learn how to resurface a concrete driveway.

Sinking concrete can lead to major property damage if you don’t solve the underlying issue. Learn what causes concrete to sink and how to fix the problem.

Learn about how thick a concrete driveway should be and what factors affect the thickness before pouring concrete to ensure safety and durability.