Building a laundry room addition to your home adds value and functionality. Your laundry room addition cost will depend on size, materials, and other factors.

Start your bathroom’s reinvention this weekend

Preformed fiberglass shower pans are standard components when remodeling a shower. But if you’re considering a custom shower to fit your new bathroom remodel plan or to achieve a specific aesthetic, you’re in the right place. DIY shower construction is a big job to consider, but the reward can be worth the effort.

Breaking shower building into smaller chunks can make a DIY shower build achievable. Let’s focus on how to build a shower base for a walk-in shower. The plan is to create a surface on which you can install whatever tile you like for a shower look that’s all your own.

You’ll need to do a little bit of prep before you start building. Mortar and tile products are heavy. Check to make sure your floor joists and subfloor are up to the job before moving forward. If your new shower requires new wall construction, complete that beforehand. Check each of these tasks off before starting shower base construction:

Check that you have space for the minimum walk-in shower dimensions.

Remove your tub (if converting a tub to a walk-in shower).

Make any necessary subfloor or joist repairs.

Outline your new shower on the floor in pencil.

Remove the drywall to about 6 feet above the subfloor in and near the shower.

At floor level, cut and install 2-by-6 blocking between each exposed stud space. Then, secure the blocks with exterior-grade screws.

It’s also important to remember the setup work, whether remodeling your entire bathroom or replacing just the shower. After the demolition of your old installation, you may choose to move the shower plumbing, install new lines, or add wiring for a steam shower. For the best results, have an electrician and plumbing pro near you assist with this part. You can start building your new shower base when the plumbing is ready.

The curb defines the shower’s outline and keeps water from immediately escaping the area if the drain clogs.

Using exterior-grade screws, affix 2-by-4 lumber lengths at the shower curb location that you drew out earlier.

Stack and secure two more layers of 2-by-4 boards on top of the first boards.

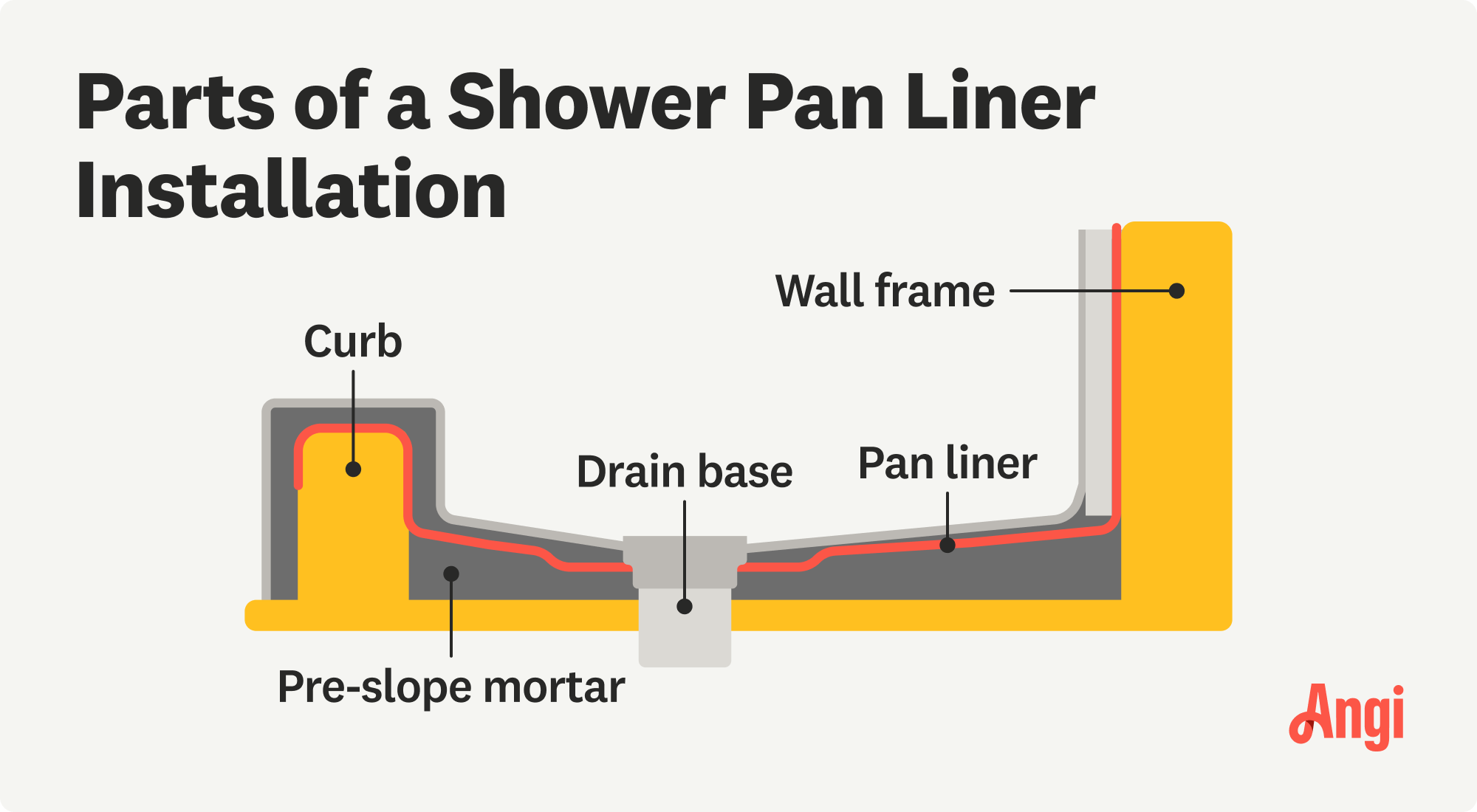

A shower floor consists of two layers. The subfloor is made of a bed of mortar and creates a slope towards the drain.

If you or the plumber haven’t already, glue the two-piece drain or other shower drain type into place.

Remove the top half of the drain and use a rag to block the drain opening.

Lay felt paper or plastic underlayment flat on the subfloor. Cut a hole in the material at the drain location to expose the drain.

The first mortar bed should meet the top of the lower drain piece. Calculate a 1/4-inch-per-linear-foot pitch away from the drain.

Mark the height of the outside edge of the mortar bed and measure the distance to the existing subfloor.

Using scrap pieces of lumber, cut several blocks (about one per foot) and place them at the outer edges of the shower to use as screeding blocks. You’ll leave these blocks in place after pouring the bed.

Mix the mortar following manufacturer's instructions in the 5-gallon pail.

Pour the mortar bed and trowel it smooth, using the screed blocks and the top of the installed drain bottom as a guide. Take care to avoid blocking the drain’s weep holes.

Allow the bed to cure overnight.

You can purchase a PVC shower pan membrane in almost any size you need at your local home center or hardware store.

Lay the membrane flat onto the mortar bed, continuing it up the walls about six inches and covering the entire shower curb.

With roofing nails, attach only the membrane’s top edge to the wall. Leave the membrane draping over the curb.

Fold the corners into themselves and tuck the excess between the corner stud spaces with a plastic taping knife. Use caution not to cut the material.

Alternatively, use a wood chisel to create a void to tuck the liner material into at the corners.

Carefully cut the liner around the drain to expose it and the connecting bolts.

Use silicone caulk to seal the cut edge to the drain piece.

Remove the stuffed rag and bolt the top half of the drain to the lower part.

Use painter's tape to cover the drain once again.

Installing tile in a wet location requires using a proper substrate. Check your local building code for any additional requirements to the following steps.

Staple a plastic sheet, felt paper, or another vapor barrier over the exposed wall studs to meet code. Avoid stapling below the top of the PVC liner.

Install cement board to code and snug against the top of the mortar subfloor. Avoid installing fasteners below the top of the liner.

Conceal the shower curb, fully encasing it with the cement board. You can use fasteners through the liner here.

Cover the exposed screw heads at the shower curb with silicone caulk.

Caulk the gap between the cement board edges and the mortar bed with silicone caulk.

An expanded metal lathe provides extra strength to your shower base.

Cut a piece, or several, of expanded metal lathe and lay them over the mortar subfloor.

Leave the drain and a 1-inch space around it uncovered.

The shower curb doesn’t need lathe coverage.

You don’t need to secure the lathe with fasteners. The next mortar bed will hold it in place.

The second mortar bed provides a finished surface for tiling.

With a pencil and straightedge or chalk line, create a line 1 1/2 inches above the subfloor’s height around the shower’s perimeter.

Adjust the drain height to create a 1-inch space between the drain’s top and the bolted-on upper part.

Mix another batch of bed mortar.

Pour, screed, and trowel smooth a second mortar bed using the chalk line and the drain’s height as your guide.

Allow the bed to cure overnight.

Your shower base is now ready for your best shower tile ideas:

Twist the drain left or right until it matches the tile height. You may have to insert needlenose pliers or another tool into the drain to get a grip.

Or, you can simply hire a bathroom tile installer near you to do the rest.

Mistakes happen, but you can save yourself thousands of dollars with a heads-up on avoidable problems. Do not start this project without checking the level of the subfloor underneath the first layer of mortar. DIYers often assume that the mortar will even out the floor, but that’s not the case.

An uneven subfloor can lead to flexing, compromising the shower’s stability over time. If the subfloor is uneven, apply a leveling compound before starting on the shower base.

Along those same lines, check the evenness of the mortar as you’re creating the slope toward the drain. Use a level to look for lumps and valleys that can be smoothed out before the mortar sets.

Finally, manufacturers’ instructions for making mortar vary, so read through them and follow them carefully. Unfortunately, simple mistakes like adding too much water can affect the mortar’s chemical composition, compromising its strength.

Shower remodeling costs range from a few hundred dollars to thousands. DIY-building a shower base costs between $150 and $200. Professionally poured shower bases cost an average of $800. Installing a preformed fiberglass shower pan has similar prices.

Building a shower base yourself isn’t an easy task, but it has a high feel-good factor when it’s complete. It can even save a few remodeling budget dollars. However, DIY shower base construction isn’t everyone’s favorite way to spend a weekend, and a costly mistake won’t save you anything on bathroom remodeling costs. If you’re not experienced or simply would rather relax on your weekend, a shower installer near you can help.

From average costs to expert advice, get all the answers you need to get your job done.

Building a laundry room addition to your home adds value and functionality. Your laundry room addition cost will depend on size, materials, and other factors.

Sink installation costs depend on the type of sink, the material, and the labor. This guide can help you budget for your project—from pedestal to farmhouse.

An entryway addition can cost thousands, but it pays off in multiple ways. Let’s look at entryway addition costs and what factors affect your total.

What is a range in a kitchen, and which is best for your cooking needs? Learn about the various types of kitchen ranges and what to consider before buying one.

Learn how to remodel a bathroom to create a serene, spa-like space to enjoy every day. Follow our guide for remodel methods and designs.

The chances of slipping and falling in the shower increase with age and limited mobility. Here are the types of shower grab bars and safety rails that can keep you safe.