Atlanta’s hot, humid climate can cause various types of roof damage. Learn how much roof repair costs in Atlanta, GA, and what affects how much you’ll pay.

Faulty roof flashing just may be the cause of your water damage

Roof flashing prevents leaks and maintains the integrity of your roof.

Various types of roof flashing serve different roof protection purposes.

Steel is the most popular flashing material, but other materials may be used.

Spotting signs of faulty flashing can save time and money if addressed early.

Without a proper roof flashing system, your entire house is susceptible to some pretty scary stuff. We’re talking about leaks and water damage, mold, rotting, and even pest infestations.

So, what is roof flashing, and how can you tell if yours needs to be replaced?

Simply put, roof flashing uses a waterproof material (normally steel) to direct water away from the most vulnerable areas of your roof.

Unless you have adequate roofing experience, we do not recommend messing with your roof flashing as a DIY project. You’ll need to bring in a local roofing professional to help you make repairs to your flashing system.

However, it’s still useful to know what roof flashing is and how it works. The more you understand what to look for, the sooner you can identify potential issues—ultimately preventing costly, severe damage.

A roof flashing system is designed to direct the flow of water off a roof, bypassing the areas that are the most susceptible to water damage.

More specifically, roof flashing materials are strategically placed to close corners and crevices where water could seep in without it (think chimneys, skylights, vents, etc.).

There are a number of reasons roof flashing is crucial for your property, including:

It stops water intrusion. The main purpose of roof flashing is to prevent water from entering areas where various roof surfaces meet or where the roof intersects with other structures, like chimneys, vents, skylights, and dormers. Proper flashing significantly reduces the risk of water intrusion, which can result in leaks, mold growth, and structural damage.

It shields against moisture damage. There’s no denying that moisture can take a serious toll on your home and roof. Roof flashing serves as a barrier, redirecting water from vital areas to prevent moisture from seeping into the roof structure and causing moisture-related damage.

It prevents expensive repairs. While roof flashing requires an up-front investment, forgoing it can lead to costly repairs in the future. Without flashing in place, you could end up paying thousands to repair water damage in the walls, ceilings, insulation, and other parts of your home.

It increases energy efficiency. If you’re looking for an effective way to make your home more energy efficient, roof flashing should be on your radar. When your flashing is correctly sealed, you’ll be able to stop air leakage and drafts. This can help maintain consistent temperatures inside your home and, in turn, lower the costs of cooling and heating.

It improves aesthetics. Roof flashing can be done in a variety of materials, such as aluminum, copper, and steel. Depending on the style of your home and the material you choose, it can add a decorative touch to your home.

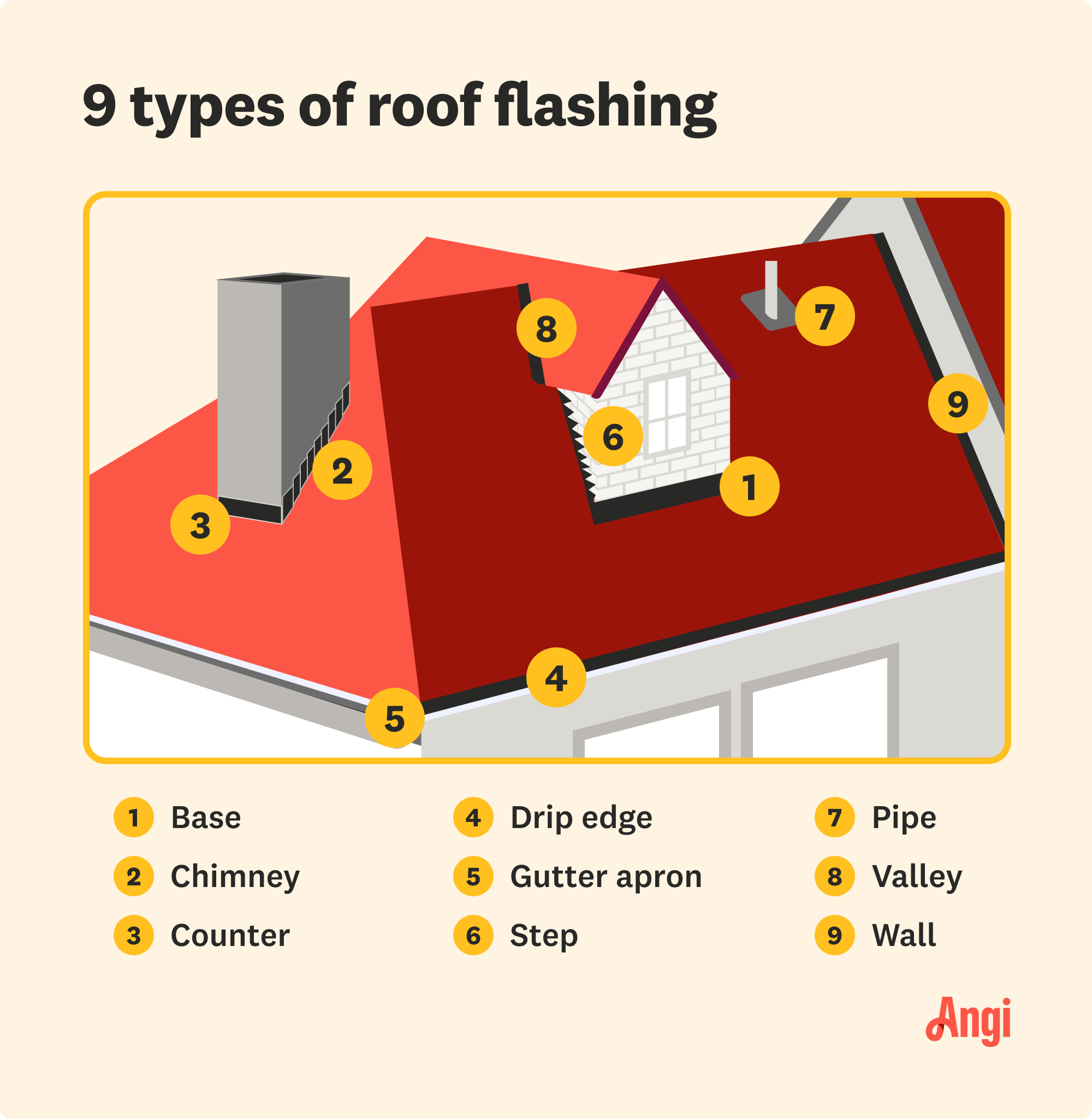

Though the overarching idea of roof flashing is the same, there are different types that fit some situations better than others. Here are seven common types of roof flashing you should know:

Base flashing helps prevent water damage at vertical-to-horizontal intersections on a roof where the roof meets a vertical wall juncture. Base flashing is installed underneath siding and shingles, so it's not easily seen.

Step flashing involves “L” shaped pieces of flashing material that are installed along the corner where the roof meets a sidewall. This type of flashing is partly visible, so homeowners may choose a more expensive material to better match their home’s exterior.

Counter flashing is placed either above or opposite the base flashing. It’s most commonly used between the roof’s surface and a chimney or a brick wall. Its purpose is to protect the base flashing.

The most effective way to install counter flashing on a chimney is actually while the chimney itself is being built. However, you can still add counter flashing to an already existing brick structure.

Continuous or apron flashing is a long piece of flashing that reroutes water from vertical walls and sloped roofs into a gutter.

Valley flashing involves using flashing materials to line the dip where two sides of a roof come together and form a valley. This helps direct running water off of the roof and into the gutters.

Kickout flashing is needed when a gutter ends against a sidewall. This kind of flashing helps prevent water from running down the sidewall and diverts it into the gutters instead.

Drip edge flashing is placed around the edges of a roof to prevent water from dripping behind the gutters and rotting out the roof in the process.

Skylight flashing protects the junction where the skylight meets the roof and uses both step flashing and counterflashing. Some skylights offer or require their own flashing kits to ensure a snug fit and proper seal to reduce the chance of leaks.

Steel is the most common roof flashing material, but you can use other materials depending on your project.

Aluminum is a lightweight material that is easy for roofers to form into the correct shape. Unfortunately, aluminum can corrode when in contact with concrete or masonry, so in order for it to stand up to these applications, it must be coated.

Copper flashing can also be shaped easily, holds up well to soldering, and is very durable. Copper is more expensive than other flashing materials and will naturally patina over time.

Steel is the most popular option for roof flashing. It can be shaped into the correct form and both stainless and galvanized steel are corrosion-resistant.

The first step in installing roof flashing is to still the underlayment, which provides a waterproofing effect. After that, the flashing itself is installed in layers. Once you’ve installed the first round of flashing around the edges, more flashing is installed in an overlapped format, and you continue to install where the next shingle is until it is complete. These steps are repeated until completion, and then the flashing is sealed with a special glue.

To ensure your roof flashing is installed correctly, you should look into how to hire a roofer to get the job done right. There are also roof financing options available to help you afford the project.

Once your roof flashing has been properly installed, it’s your responsibility to maintain it. Here are several strategies to help you do so:

Perform Ongoing Inspections. Inspect your flashing at least twice per year to look for any damage or signs of wear and tear. Assess it for cracks, rust, or missing pieces. Ideally, you’d perform your inspections in the spring and fall or after extreme weather events that can damage your roof, like hail or wind.

Replace or Repair Flashing As Necessary. Hopefully, you won’t have to replace your roof flashing for a while. However, if you notice damage during your inspection, be sure to repair or replace it right away. A roofing professional can inform you whether you’re due for new flashing or could get away with a repair.

Commit to Regular Cleaning. It’s important to clean your roof flashing on a regular basis as dirt and other debris can accumulate on it over time and reduce its effectiveness. You should hire a roofer near you to do this work, as getting up on your roof is dangerous. Routine cleaning is key if you’d like to prevent water damage and extend your roof’s lifespan.

Unless you’re an experienced roofing professional, it may be difficult to notice when your flashing system needs to be replaced, but you can look out for these easy-to-spot signs:

Noticeable corrosion and rust in flashing and gutters

Curling or broken shingles

Patches on the roof

Water damage in the attic or interior walls (water stains, mold, etc.)

Spotting signs of flashing issues and addressing them early can help prevent damage to the roof and cost less than the full roof replacement cost. It also gives you a chance to spot signs you need a full roof replacement. Once you know what needs to be done, you should take a look into roofers near you to find the contractor best suited to your project and budget.

From average costs to expert advice, get all the answers you need to get your job done.

Atlanta’s hot, humid climate can cause various types of roof damage. Learn how much roof repair costs in Atlanta, GA, and what affects how much you’ll pay.

Metal roofs stand up better to severe weather than asphalt shingles. See how much a metal roof costs in Atlanta to see if this upgrade is within your budget.

A new roof boosts curb appeal and home value and sets you up for decades of home protection. Learn about roof replacement costs in Atlanta to set your budget.

Sharpen your skills and smooth your cuts with this DIY guide to cutting metal roofing. We cover everything from measurements and safety gear to which tools will give you the cleanest cut.

If you need a new flat roof, learn about tar and gravel roof costs and what can affect your total to make sure you budget accurately.

Roof insulation types include batts, spray foam, rigid foam boards, and fiber cement boards. Keep reading to learn which roof insulation is best for your home.