Learn all the factors that influence the cost to install a heat pump water heater at your home.

Expanding on a common boiler question

Expansion tanks must be installed on the supply side of the boiler—where cooler water enters the boiler to be heated again.

Expansion tanks must be installed between the boiler and the circulator, and they must be 18 inches or more away from the boiler’s vent connector.

Most expansion tanks work properly when standing upright, but some models allow for a horizontal installation.

Signs of a poorly installed expansion tank include rapid pressure increases, strange new noises, and malfunctioning bleed valves.

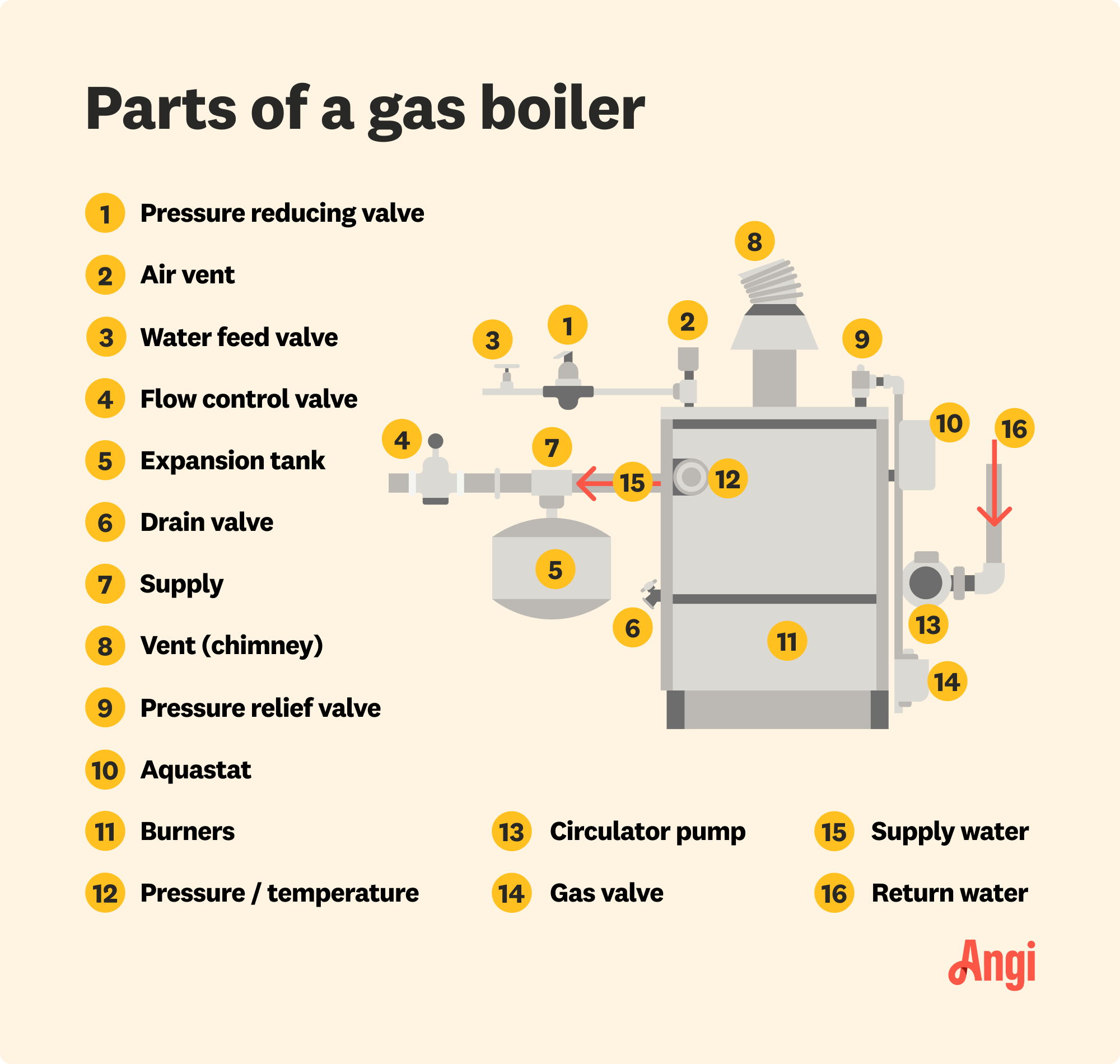

Wondering where the expansion tank should be installed on your boiler? The expansion tank, or thermal expansion tank, is a 3 to 5 pound tank that sits close to boilers and water heaters, performing a small but necessary function. Inside is a trapped pocket of air that expands and contracts in response to pressure. When water is heated, it expands, so the tank allows water to expand and pushes back as the water cools, keeping the pressure at safe levels while heating the water to high temperatures.

To do that job properly, the expansion valve needs to be installed in the right spot on the boiler. Let’s dive into the details of where to install an expansion tank and when to hire a boiler professional for help.

The most common spot to install the expansion tank on a boiler is slightly above or close beside the boiler—wherever it’s easiest to strap the tank in next to the supply pipe and secure it for the long term. Here are the rules that the tank placement should follow:

The tank should be installed at least 18 inches from the vent connector of the boiler.

The tank must be installed on the supply side of the boiler, not the “cool” side of the boiler where returning water comes. Supply pipes are usually higher and marked with the direction of water flow.

The tank should usually be installed upright.

The tank must be properly supported with metal straps or brackets. It cannot be attached to the piping and left to hang.

The tank must be installed between the shut-off valve and the tank inlet.

The tank must be installed above the pressure relief valve on the boiler.

If the boiler has a system circulator on the supply side, the expansion tank must be installed between the boiler and the circulator.

Boiler manuals have more specific instructions for installation. Keep in mind that larger boilers may need larger expansion tanks. Consider hiring a local boiler installer to add an expansion tank, ensuring a high-quality and long-lasting placement.

If you’re worried that your expansion tank is in the wrong position, there are several signs that something has gone wrong. Look for these clues, especially if they happen right after an expansion tank installation.

A completely upside-down tank: Some expansion tanks have the option to place them horizontally, but the tank should never be installed upside-down. That prevents the air from condensing properly

Leaks from a new expansion tank: A new leak could indicate an installation on the wrong part of the system or with the wrong connections, especially if it starts leaking immediately when you turn the boiler system on. If multiple leaks suddenly appear after a new tank installation, that could mean the tank is failing to do its job.

Misbehaving faucets: If you turn on your faucets and the water shoots out extra-hard for the first several seconds, then your system is over-pressurized. One cause is a malfunctioning expansion tank that isn’t allowing the proper contraction and expansion of air. This only applies to boilers that also heat water for heating.

Rapid (and dangerous) pressure increases: If heated water doesn’t have any place to push extra air, then it will quickly raise the pressure of the boiler into the danger zone. If you see the pressure gauge showing alarming signs, shut it down and consult a boiler professional.

Malfunctioning bleed or relief valves: Bleed and relief valves normally bleed out excess air from the system. But if these valves immediately leak water without bleeding out air, the expansion tank likely has an issue.

A dull thudding sound: Give the tank a rap with your knuckles when the boiler is turned off. A healthy expansion tank should have a clear, hollow sound, showing that it’s filled with air. If the tank has a dull thud instead, it may be filled with water and not working properly.

Alarming cracking noises: When a boiler system can’t deal with pressure properly, the pipes and pipe joints suffer the most. This can create alarming popping and cracking noises, especially once the boiler is turned off and the pressure on the pipes eases.

Excellent work, quick turnaround and reasonable price. Dustin was a pleasure to work with. It was a small job but he took care of every detail and left a good finished product. Would definitely recommend and rehire.

They came to our home . Very professional.

Very professional installation with above-and-beyond analysis of our issues. Our older home had an old electric boiler tank in the corner of the kitchen and I thought the tankless might go there...but Peter walked through and suggested a more efficient and cost-saving way to install at a...

The work was outstanding. When removing old concrete they discover it was not filled properly and had to order more gravel. They were very professional. Arrived on time and stayed until job was completed. The cement truck was 4 hours late and they stated until 10 PM to complete the job.

Replacing old copper pipe with flex lines and valves on hot/cold water connection.

Scott is very dependable and professional. He communicated with me every step of the way and always showed up when he said he was going to. Worked very efficiently, cleaned up the job site, and left me with a beautiful new fence!

The team replaced my tile shower from 1952. I had rotten wood under the floor, a water leak, and black fungus on the tile. They did a FANTASTIC job. The new shower looks GREAT! HAPPY, HAPPY, HAPPY!!!!!!!

We had a leak we thought was under the house but it was found to be coming from the hot water heater in the utility room. Brandon found the leak and fixed it promptly. He was very polite, professional and answered all our questions. We would totally recommend delcor inc.

Excellent. They were on time. Very professional. They even moved an old water heater we had in the attic and hauled it away for free.

This was on a weekend....a wet hardwood floor-- when I walked into the kitchen,opened the cabinet and found 2 inches of water throughout the cabinet,all supplies wet, a mess. Responded in an hour and stayed for about 3hours.

From average costs to expert advice, get all the answers you need to get your job done.

Learn all the factors that influence the cost to install a heat pump water heater at your home.

A water heater flush costs $160 on average but can vary based on the unit size, type, labor, location, and more. Keep reading to learn how much you could pay.

Learn about the different factors that go into water heater gas valve replacement costs to see if you should DIY the project or call a pro.

Are heat pump water heaters worth it? These energy-efficient systems help you save on utility bills. Here’s why heat pump water heaters are worth it.

How long does an electric water heater last? We’re breaking down what you need to know about electric water heater longevity. Read on to learn more.

How much do water heaters weigh? The answer depends on the type of water heater, its size, and several other factors. Read on to learn more.