How much does it cost to paint a room? Learn what you’ll pay to give your space a makeover, depending on room size, paint type, the pro you hire, and more.

Precision or power? The choice is yours

Sandblasting is easier for the average DIY homeowner to tackle.

Laser cleaning minimizes dust and debris during removal, making it an environmentally friendly option.

Sandblasting costs less than laser cleaning at $1.50 to $7 per square foot.

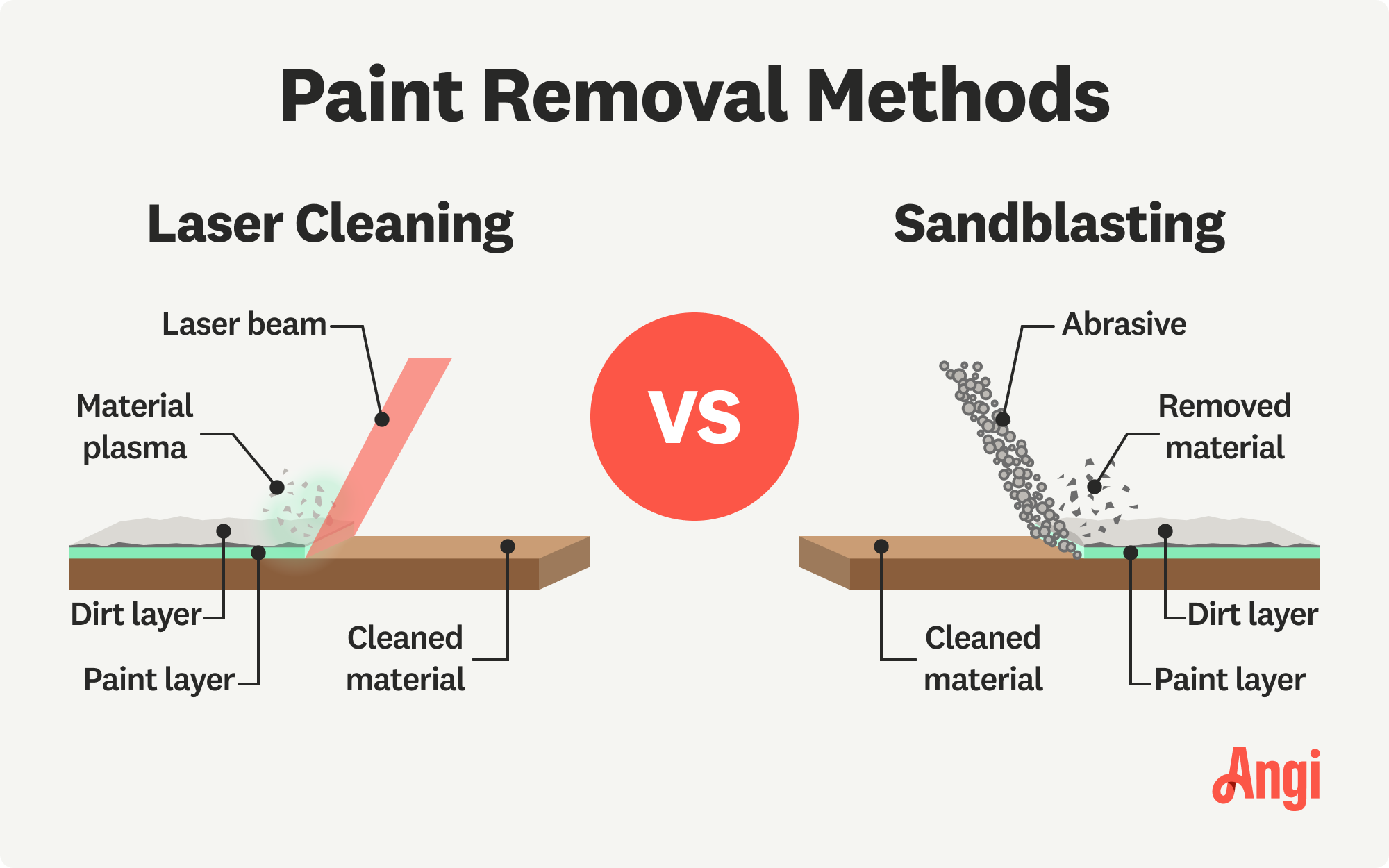

Laser cleaning and sandblasting are both effective paint-stripping methods you can use at your home. While sandblasting has long been a go-to solution for tough, industrial cleaning jobs, laser cleaning offers a more precise, eco-friendly alternative that’s gaining popularity for delicate or detail-oriented projects. Dive into the key differences between laser cleaning and sandblasting so you can choose the right approach for your next paint removal project.

Laser cleaning and sandblasting are effective methods for removing paint, but the processes are different. Laser cleaning uses focused laser beams to vaporize paint and contaminants with high precision. Its use is ideal for delicate surfaces, minimal waste, and environmentally sensitive projects.

But what is sandblasting? The process involves propelling abrasive materials at high speeds to physically strip away paint, which is more aggressive and better suited for tough, industrial jobs or heavily rusted surfaces. Sandblasting can generate significant dust, damage softer materials, and require more extensive cleanup, whereas laser cleaning offers a cleaner, more controlled alternative with less surface wear.

Laser cleaning is an alternative to sandblasting that removes paint using a non-contact method. High-energy laser pulses heat and vaporize the paint without damaging the underlying material. The process is ideal for precision work on delicate or valuable items. It's a clean, eco-friendly alternative to abrasive methods.

| Pros | Cons |

|---|---|

| Precise and gentle | High equipment cost |

| Environmentally-friendly | Slower process |

| Minimal waste and dust kick-up | Less effective on thick paint |

Best for:

Small, detailed areas that require accurate removal

Delicate or sensitive surfaces

Keeping cleanup minimal

As a non-contact, non-abrasive method, laser cleaning won’t damage the underlying material, making it perfect for removing paint from delicate surfaces like soft metals, artwork, or historically significant items. It also produces minimal waste and dust, which cuts down on cleanup time and improves air quality in enclosed areas. Since it doesn’t rely on chemicals or abrasive blasting media, it’s also considered an environmentally-friendly solution.

Laser cleaning equipment requires relatively low maintenance compared to abrasive systems. Because there's less mess involved, there's less overall downtime between cleaning tasks. For projects where cleanliness, precision, and preservation matter most, laser cleaning is a standout choice.

One of the biggest barriers to laser cleaning is the high initial cost of the equipment, which can be a significant investment. The process is slower than traditional paint removal methods, especially when working on large surface areas or thick, multi-layered coatings. It also requires hiring a local paint-stripping expert who understands how to adjust settings for different materials and conditions.

While laser cleaning is highly effective on certain surfaces, it may struggle with heavy-duty coatings or when quick turnaround times are needed. These factors can make it less practical for some projects despite its many precision and environmental benefits.

Sandblasting removes paint by forcibly propelling abrasive materials like sand, glass beads, or grit at high speeds onto a surface. This abrasive action strips away paint and is ideal for heavy-duty cleaning or prepping surfaces for refinishing. It's a fast and effective solution, especially for large projects.

| Pros | Cons |

|---|---|

| Fast and effective | Produces dust and debris |

| Removes multiple layers | Not environmentally friendly |

| Works on tough materials | Can damage soft or delicate surfaces |

Best for:

Tackling thick or heavy coats of paint

Use on durable materials

Large surface areas

Sandblasting is highly effective at removing paint on large or heavily coated surfaces. Its speed and efficiency make it perfect for industrial or commercial projects where time and coverage matter. It works well on tough materials, such as metal, concrete, and brick.

Sandblasting can remove multiple layers of paint in one go, saving time and effort compared to more precise or slower methods. The aggressive cleaning also helps prep surfaces for new paint, coatings, or finishes by creating a texture that improves adhesion.

Sandblasting is powerful, and while that's great for tough surfaces, it can be too harsh for softer or more delicate surfaces. On these surfaces, there's a risk of pitting, etching, or warping. This makes it unsuitable for detailed work or restoration projects where surface preservation is important. Additionally, the abrasive nature of sandblasting can require extra surface finishing or smoothing afterward, adding time and effort to the overall project.

Sandblasting creates a mess of dust and debris that requires extensive cleanup and proper containment, especially in indoor or enclosed areas. Safety is also a concern, as operators must use protective gear to guard against inhaling dust or being injured by abrasives. From an environmental standpoint, it’s not the most eco-friendly option due to waste generation and airborne particles, which may require additional filtration or disposal procedures to stay compliant with regulations.

Here’s how these two paint-stripping methods stack up against each other.

Thanks to its precise and less abrasive process, laser cleaning results in a better appearance than sandblasting. Laser cleaning doesn’t physically scratch or damage the underlying material, leaving surfaces smoother and cleaner, without the rough texture or potential for pits and marks that sandblasting can cause.

Depending on your needs, laser cleaning and sandblasting can boast durability benefits. Laser cleaning preserves the integrity of the material, while sandblasting's rougher texture can better support coatings that need to withstand wear and tear.

Sandblasting costs less, between $1.50 and $7 per square foot. However, the total cost will vary based on the surface area and the intensity of the cleaning. Most homeowners pay around $3,200, but the cost can range between $1,500 and $12,000. Laser cleaners are more expensive, starting around $4,700, and you have to factor in learning the equipment and taking the time to complete the job.

Sandblasting is easier to DIY because the equipment is more accessible and affordable for home use. A basic sandblasting setup involves a compressor and abrasive media, which you can rent or buy relatively easily. The process is straightforward and doesn't require skilled knowledge or training beyond general safety precautions. Laser cleaning requires a significant investment and technical expertise to operate properly, making it impractical for most DIYers.

Laser cleaning is a more eco-friendly option because it doesn’t produce waste or require the use of abrasive materials. Unlike sandblasting, which generates dust and debris that need to be collected and disposed of, laser cleaning operates with minimal environmental impact. It only vaporizes the paint without leaving behind secondary waste. Laser cleaning also doesn’t rely on chemicals or harmful media, making it a cleaner option for removing paint.

From average costs to expert advice, get all the answers you need to get your job done.

How much does it cost to paint a room? Learn what you’ll pay to give your space a makeover, depending on room size, paint type, the pro you hire, and more.

The cost to paint the interior of a house in St. Louis, MO depends on size, layout, type of surface, and more. Learn what factors can influence your total in this guide.

The cost to paint the interior of a house in Denver, CO depends on size, layout, type of surface, and more. Learn what factors can influence your total in this guide.

There are many alternatives to painting brick walls, including staining and whitewashing. Learn more about different methods for bringing new life to your brick space.

If your room is falling flat, learning how to texture walls will help bring dimension to your space. Get to know all the different options and how to do them yourself.

What are the best basement paint colors? Check out our guide to learn the wall colors that will make your basement feel bigger, brighter, and more inviting.