Wondering how much shower valve replacement costs? The answer depends on type, labor, and materials—but foresight and research can save you some money.

Don’t just go with the flow—learn the difference between these two common valve types

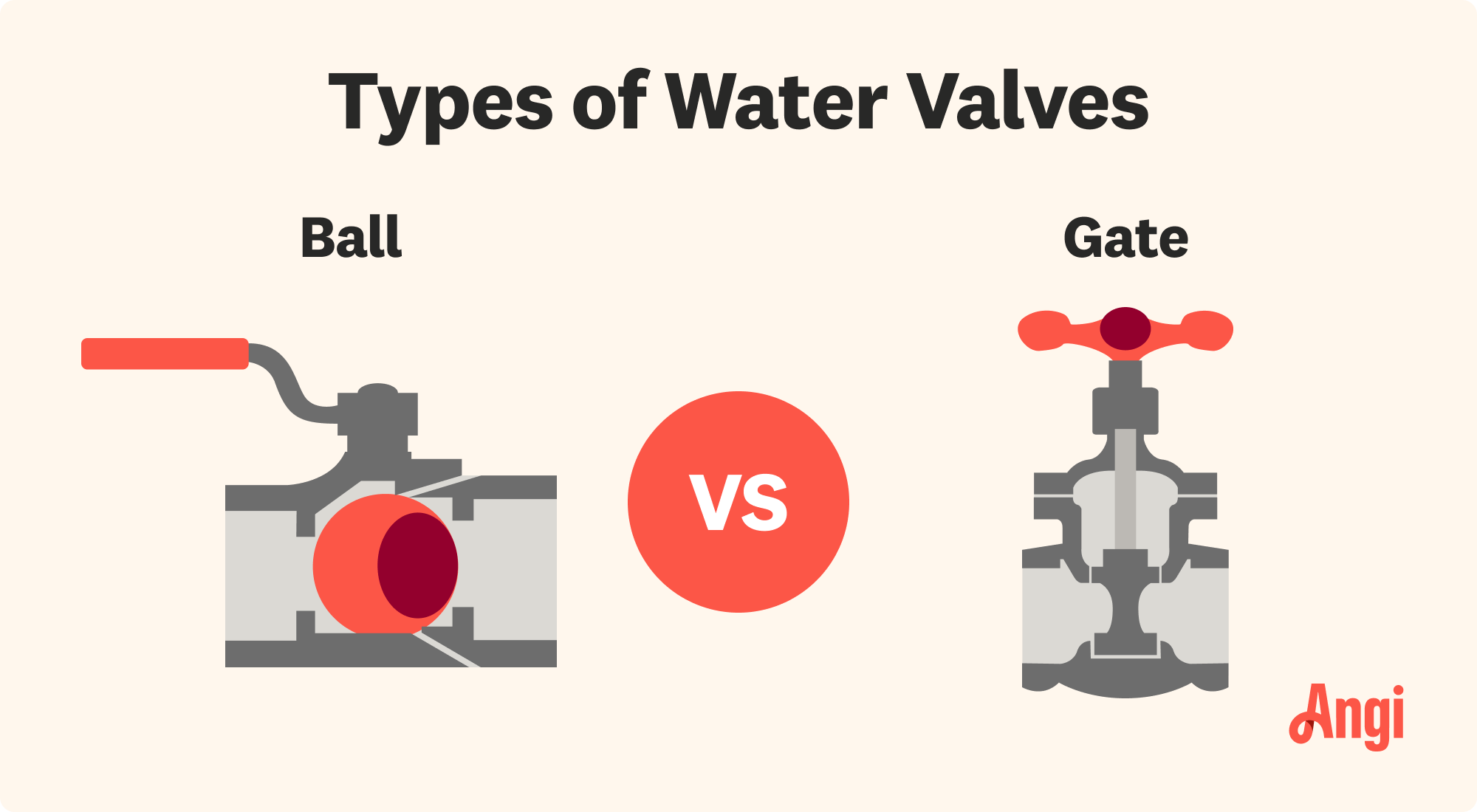

Both ball valves and gate valves control the flow and pressure of fluids.

Ball valves are compact in size and require less maintenance.

Gate valves are budget-friendly but are prone to clogging.

Ball valves are best suited for frequent operation with quick on/off controls.

Gate valves are ideal for infrequent operation.

Choosing the right type of valve for your home plumbing or gas system is extremely important. Valves control the flow and pressure of fluids, ensuring that your system runs safely and efficiently. Ball valves and gate valves are two popular types of valves. Comparing a ball valve versus gate valve in categories such as design, cost, maintenance, space, and location can help you make an informed decision.

Both ball valves and gate valves control the flow of liquid or gas through their respective systems. However, there are several differences between these two common valve types. A ball valve, also known as a shut-off valve, is smaller in size and easier to maintain. While ball valves are more expensive, they can be quickly shut on and off while providing a tighter seal.

Gate valves, or sluice valves, are more budget-friendly but also clog easily—requiring more maintenance over time. Due to their design, gate valves are bulkier and need more vertical space. Gate valves are ideal for applications that require full flow and minimal pressure drop.

| Type of Difference | Ball Valve | Gate Valve |

|---|---|---|

| Appearance | Compact with a lever handle and round body | Tall and cylindrical with a wheel handle and flat body |

| Cost | Can be more expensive | Budget-friendly |

| Maintenance | Easier to maintain and clean | Harder to clean due to clogging |

| Space | Smaller in size but requires a bigger operating space | Bulkier, requires more vertical space |

| Application | Quick shut-off, ideal for frequent operation | Best for infrequent operation, ideal for full flow and minimal pressure drop |

Each with their own unique design, ball valves and gate valves differ in appearance. A gate valve has a round, wheel-shaped handle that must be turned 360 degrees to change the gate’s position. Gate valves have a tall and cylindrical body with either a rising or non-rising stem, depending on the design. When you turn the handle of a gate valve, an internal gate rises or falls to control the rate of water flow.

A ball valve has a short, straight-lever handle with a smaller, rounder body. Instead of a gate, there’s a ball-shaped hole inside of the mechanism. Ball valves only need to be turned 90 degrees to start or stop the flow of fluid.

When it comes to initial cost, gate valves are more affordable than ball valves due to their simple internal design. The exact price depends on size and material. However, you can expect to pay anywhere from $10 to $50 for the valve itself. Keep in mind, though, that gate valves are prone to corrosion and valve replacement costs can add up quickly.

Ball valves come in similar price ranges between $10 and $50, but larger valves can cost hundreds. Despite their high price tag, ball valves are easier to maintain and very durable, which can make the investment worthwhile.

It’s crucial to perform regular maintenance on both gate valves and ball valves. Ball valves often require less maintenance for several reasons. For one, they have a quarter-turn mechanism that allows for quick on/off operations. This, along with a tight seal, results in minimal wear on the valve. Ball valves are also equipped with self-cleaning features that reduce buildup, making maintenance much easier and cost-effective.

Gate valves are susceptible to clogging as the internal gate wears down over time. They’re also prone to leaking and corrosion, especially as the system ages. Maximizing the lifespan of your gate valve will require you to take the valve apart regularly to clean or replace internal parts. You can hire a professional plumber in your area for this service for the best results.

If you’re working with limited space, consider opting for a ball valve instead of a gate valve. Equipped with a quarter-turn handle and short body, ball valves are smaller in size. However, ball valves do require more lateral space to operate the handle. On the other hand, gate valves have a taller, bulkier design and require more vertical space.

Ball valves are ideal for on/off control in systems that need quick water flow, such as in plumbing, gas lines, and industrial automation. Gate valves are better suited for infrequent operations where water flow needs to be fully opened and closed. Gate valves are commonly used in water supply and irrigation systems where minimal pressure drop is essential.

From average costs to expert advice, get all the answers you need to get your job done.

Wondering how much shower valve replacement costs? The answer depends on type, labor, and materials—but foresight and research can save you some money.

Whether you’re changing your home’s floor plan in a remodel or just replacing old, worn-out plumbing, this guide will help you estimate the cost of repiping a house.

The cost to replace polybutylene pipes runs between $150 and $5,100. Find out why you need to replace your pipes now—and how much you’ll spend.

Looking for the best kitchen sink materials? We’ve got you covered. Here’s a comprehensive list of kitchen sink materials and how they measure up.

You never know when learning how to unclog a toilet will come in handy. Get to know these eight methods for the next time things stop flowing.

Follow this guide to learn how to install a kitchen sink drain, from shutting off the water supply to lowering the drain outlet and connecting the P-trap.